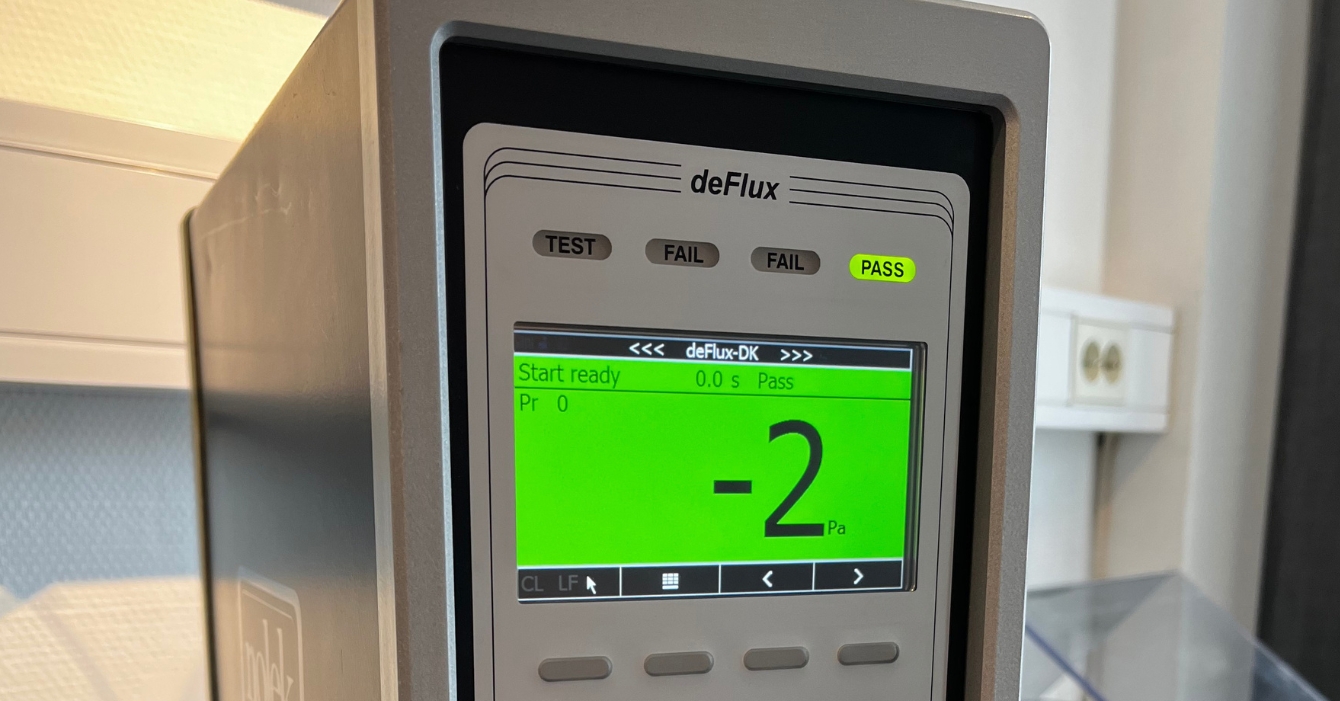

Electronics used in automotive, telecom, and industrial environments must survive far more than basic IP rating tests…

Proving Environmental Protection with Advanced Leak Testing

An IP rating on a product may look impressive, but for electronics manufacturers, a label on paper is only the beginning…

Leak Test Workflows for High-Mix Electronics Lines

High-mix electronics manufacturing demands speed, control, and confidence in test outcomes. The Nolek CES solution provides:

Micro-leak detection without contamination…

Are Your Helium Leak Tests Giving False Positives?

Helium leak testing is one of the most accurate and sensitive methods for detecting micro-leaks in sealed components. But for many manufacturers, it comes with a frustrating problem: false positives…

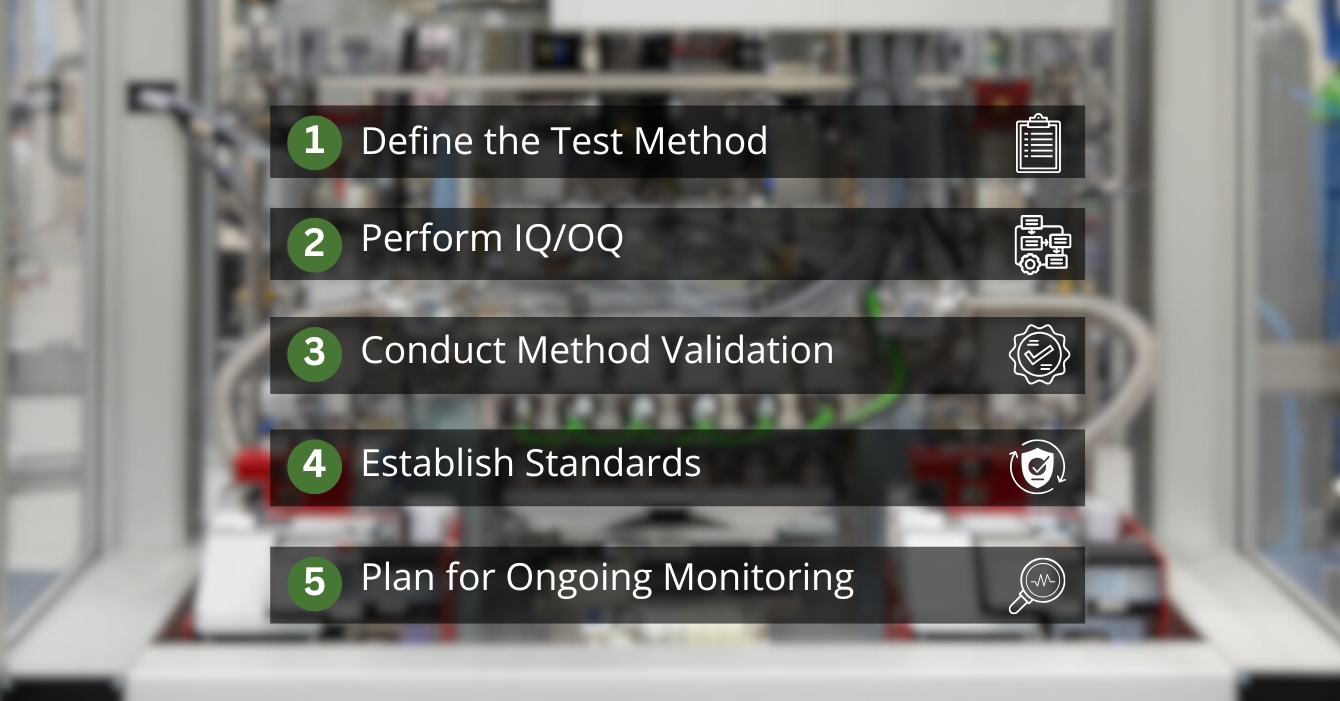

How to Validate Your Leak Testing Process in 5 Steps

In regulated industries like pharmaceuticals and MedTech, it’s not enough to simply perform leak testing you need to prove that your process is accurate, repeatable, and compliant. That’s where validation comes in…

How Global Electronics Manufacturers Standardize Leak Testing Across Facilities

As electronics manufacturing expands across continents, consistency becomes a competitive advantage. For global OEMs producing control boxes, sensor housings, or communication modules…

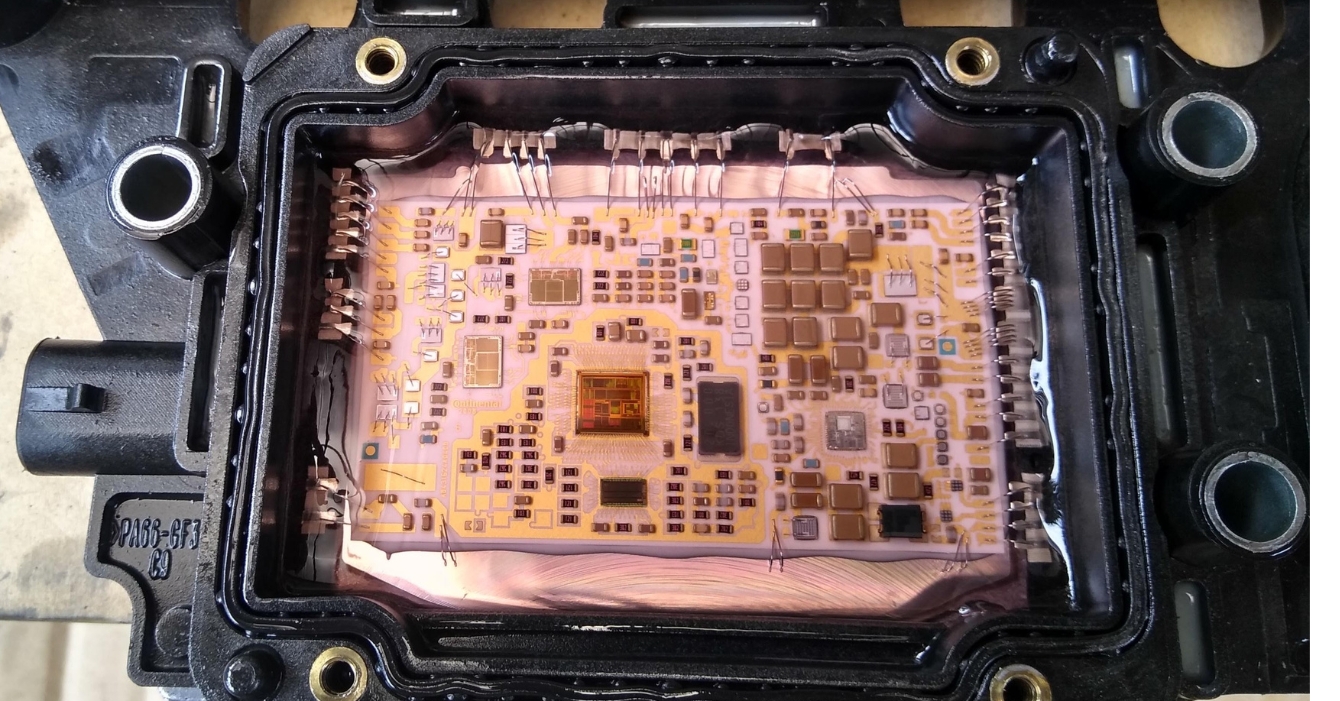

Why Micro-Leak Testing is Critical for EV Battery Modules and Sensor Systems

As electric vehicles (EVs) evolve, the pressure on manufacturers to ensure the performance and reliability of every sealed component continues to grow.