In regulated industries like pharmaceuticals and MedTech, it’s not enough to simply perform leak testing you need to prove that your process is accurate, repeatable, and compliant. That’s where validation comes in.

Leak test validation ensures that your system does what it’s supposed to do; detect real leaks, reject bad parts, and pass good ones-every time, under real-world conditions. But validation doesn’t need to be a bottleneck. With the right steps, it can become a streamlined part of your quality assurance strategy.

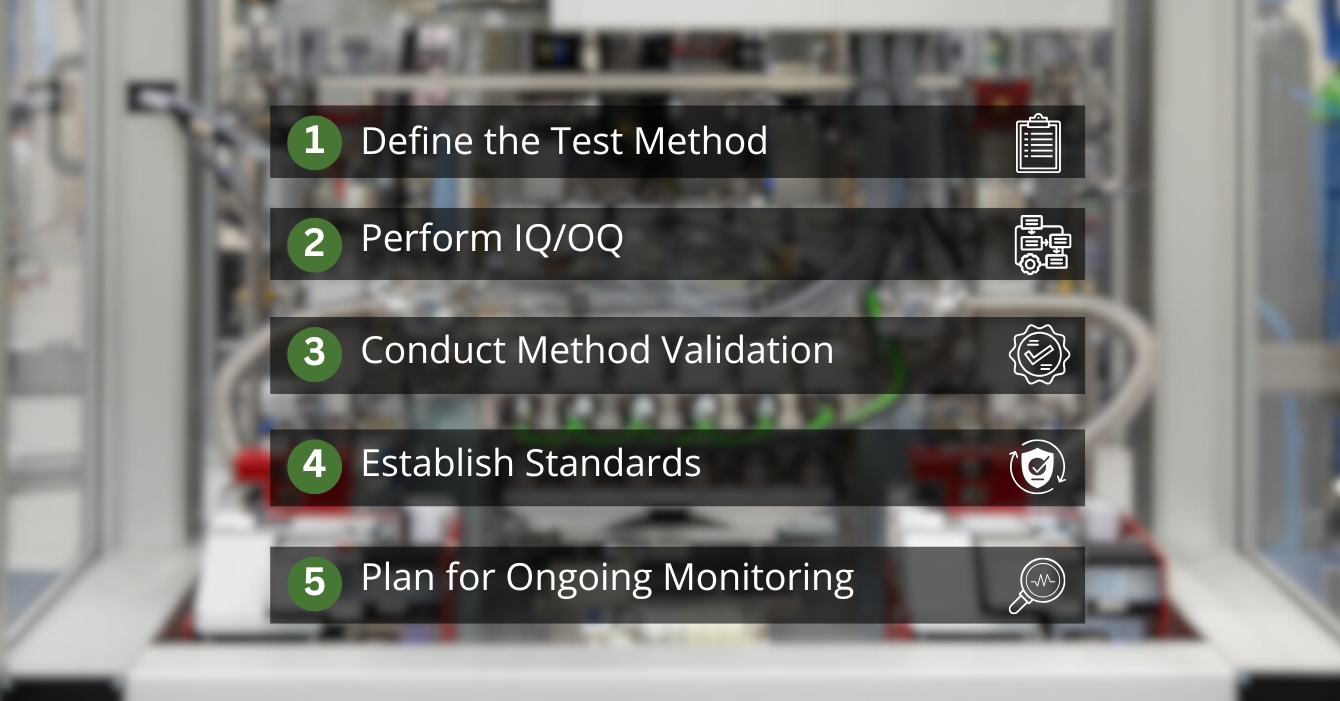

Here’s how to validate your leak testing process in five clear, audit-ready steps.

Step 1: Define the Test Method and Acceptance Criteria

Every validation starts with clarity. Select the leak testing method that aligns with your product, packaging, and risk profile; whether that’s vacuum decay for parenteral vials, helium detection for electronics, or pressure decay for control boxes.

Then, define:

- Target leak rate (e.g., 1 x 10⁻⁵ mbar·L/s)

- Maximum allowable leak limit (MALL)

- Test duration and pressure parameters

- Environmental conditions (temperature, humidity, etc.)

These values form the basis of your validation protocol and your long-term quality specification.

Step 2: Perform Installation and Operational Qualification (IQ/OQ)

Once your system is set up, you’ll need to formally document:

- Installation Qualification (IQ): Verifies that all hardware, software, and utilities are installed correctly. Includes power supply checks, software version control, and component inventory.

- Operational Qualification (OQ): Confirms that the system performs to spec across the full range of conditions. Includes empty chamber testing, fixture repeatability, and basic pass/fail thresholds.

PS. Nolek provides templated documentation and engineering support for these phases, reducing internal effort and accelerating project timelines.

Step 3: Conduct Method Validation with Positive and Negative Controls

To prove that your test method is suitable, you must demonstrate:

- Specificity: The system correctly identifies leaking vs. non-leaking components

- Sensitivity: You can reliably detect leaks at or below the defined threshold

- Repeatability and Reproducibility: The test gives the same results over time and across operators or stations

Use calibrated leak standards and challenge parts (both passing and failing) to verify system behaviour.

PS. Nolek offers traceable leak artifacts and tuning support for real-world validation.

Step 4: Establish Traceability and Documentation Standards

Your validation is only as strong as your paperwork. To stay audit-ready:

- Record calibration logs, test sequences, and pass/fail outcomes

- Use digital data logging with operator ID and timestamps

- Implement electronic signatures where CFR Part 11 compliance applies

- Align all records with your QMS or MES system for real-time access

This traceability is essential for compliance with ISO 11607, USP <1207>, EU GMP Annex 1, and IATF 16949.

Step 5: Plan for Ongoing Monitoring and Requalification

Validation isn’t a one-time event. Over time, parts wear out, fixtures drift, and process conditions change.

Build revalidation into your quality plan by:

- Scheduling routine system calibration

- Rechecking test fixtures and leak limits during product changes

- Setting up automated alerts or dashboards to flag anomalies

- Maintaining change control logs for hardware or software updates

PS. Nolek offers service contracts and periodic reviews to help customers maintain validated performance over time.

Final Thoughts

Validating your leak testing process doesn’t need to be overwhelming. When broken down into clear steps: method definition, IQ/OQ, method validation, documentation, and maintenance, it becomes a predictable, manageable process that protects product integrity and regulatory standing.

If you’re launching a new product or upgrading your QA line, Nolek is here to help make leak test validation easier, faster, and more reliable.