As electronics manufacturing expands across continents, consistency becomes a competitive advantage. For global OEMs producing control boxes, sensor housings, or communication modules in multiple locations, one challenge shows up again and again, how to standardize leak testing across every facility.

Without a unified strategy, manufacturers face inconsistent pass/fail thresholds, training gaps, and quality drifts that lead to rework, warranty issues, or even recalls. The solution? A leak testing approach that scales globally while remaining flexible locally.

Let’s break down how leading electronics companies make it happen.

Why Standardization Matters

Leak testing is often one of the final steps in the production process. At this stage, inconsistency isn’t just inconvenient, it’s expensive.

Here’s what happens when leak testing isn’t standardized:

- Different sites use different methods or sensitivity thresholds

- Operators apply manual or subjective inspection techniques

- Revalidation is required every time tooling or components change

- Test data is logged inconsistently, making traceability difficult

- Global quality benchmarks are difficult to enforce

In contrast, standardized leak testing helps manufacturers reduce scrap, accelerate NPI timelines, and maintain compliance across the board.

What Standardized Leak Testing Looks Like

1. Common Testing Methods Across Sites

Whether it’s vacuum decay, helium mass spectrometry, or pressure decay, selecting a single core method across all global locations helps align sensitivity, regulatory standards, and process documentation.

2. Consistent Equipment Platform

Using the same Nolek platform across facilities simplifies training, spare parts, maintenance, and troubleshooting. It also allows you to transfer knowledge easily from plant to plant.

3. Unified Test Protocols and Fixtures

Test parameters, pass/fail limits, and clamping conditions are locked in and replicated globally. This reduces false failures and speeds up product validation in new regions.

4. Data Integration with Central Systems

Test results from all sites flow into a shared MES, ERP, or QMS, supporting full traceability and giving global quality teams a single source of truth.

5. Validation Documentation and Change Control

Standardized IQ/OQ templates and audit-ready protocols simplify regulatory compliance and internal reviews, especially when adding new sites or products.

Key Benefits for Global Operations Teams

- Faster scale-up and tech transfer to new facilities

- Reduced variation and failure analysis time across sites

- Improved CAPEX efficiency with centralized procurement

- Streamlined training and support for engineering and QA staff

- Clear compliance trail for ISO, IATF, CE, or customer audits

In a landscape where manufacturing speed and consistency are important, standardizing leak testing builds reliability into every layer of your global operation.

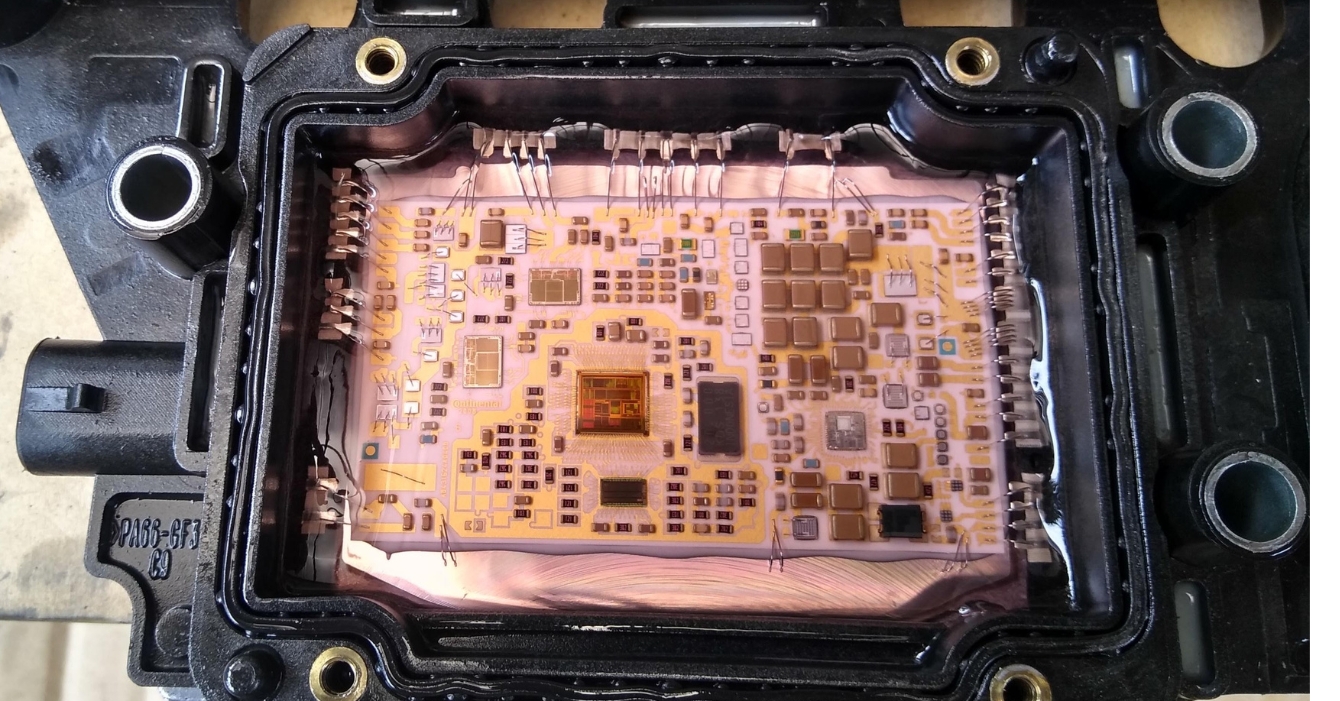

Real-World Example: Electronics Control Boxes

Imagine an electronics manufacturer producing sealed control units in Sweden, Germany and the U.S. Each site has different ambient conditions, production rates, and housing variants, but all must meet the same IP67 standard.

By deploying a unified leak test system from Nolek, they ensure that every box, regardless of origin, meets identical quality requirements with the same test fixture, cycle time, and data logging.

That consistency not only reduces internal variation, it builds confidence with end customers and auditors.

How We Support Global Standardization

Nolek has decades of experience working with multinational electronics and automotive brands to roll out standardized leak testing systems across continents.

We offer:

- A scalable platform architecture with localized configuration

- Global service and validation support in Europe, North America, and Asia

- Training and documentation aligned with your corporate quality systems

- Engineering teams that understand both high-volume automation and flexible development setups

Whether you’re rolling out a new product line or upgrading legacy systems, we help ensure that leak testing never becomes the weak link in your quality chain.

Final Thoughts

Leak testing is a small part of the production process, but when done right, it delivers big results. By standardizing across your global sites, you gain speed, control, and confidence in every unit you ship.