Manufacturers generate more leak test data today than ever before. Yet many plants still treat the information as a simple pass-fail record, filed away for audits rather than used to improve performance…

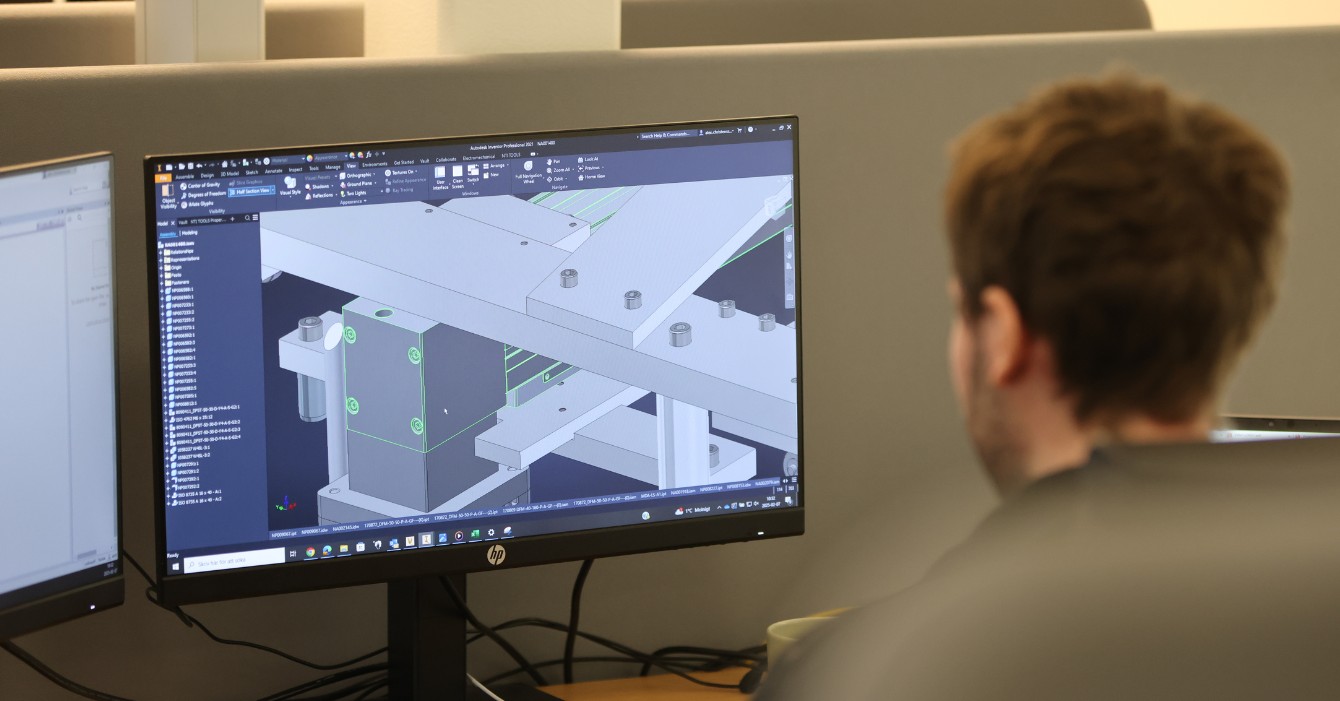

Short-Run, High-Mix Electronics Production: How to Prevent Test Bottlenecks

Electronics manufacturers increasingly operate in environments where product families shift frequently, order volumes fluctuate, and new variants appear with little notice…

The Future of Pharma Packaging: Leak Testing Strategies for Emerging Formats

Pharmaceutical packaging is changing fast. New delivery systems, novel polymers, foil-free blisters, and advanced sterile formats are reshaping how manufacturers design, qualify, and monitor container closure integrity…

How Micro-Leaks Become Major Risks in Parenteral Products

Parenteral products demand absolute confidence in sterility and container closure integrity. Even the smallest leak can compromise a batch…

Why Your Supplier Approval Process Needs Leak Test Data

More OEMs in electronics, automotive, and telecom sectors are tightening their supplier approval processes…

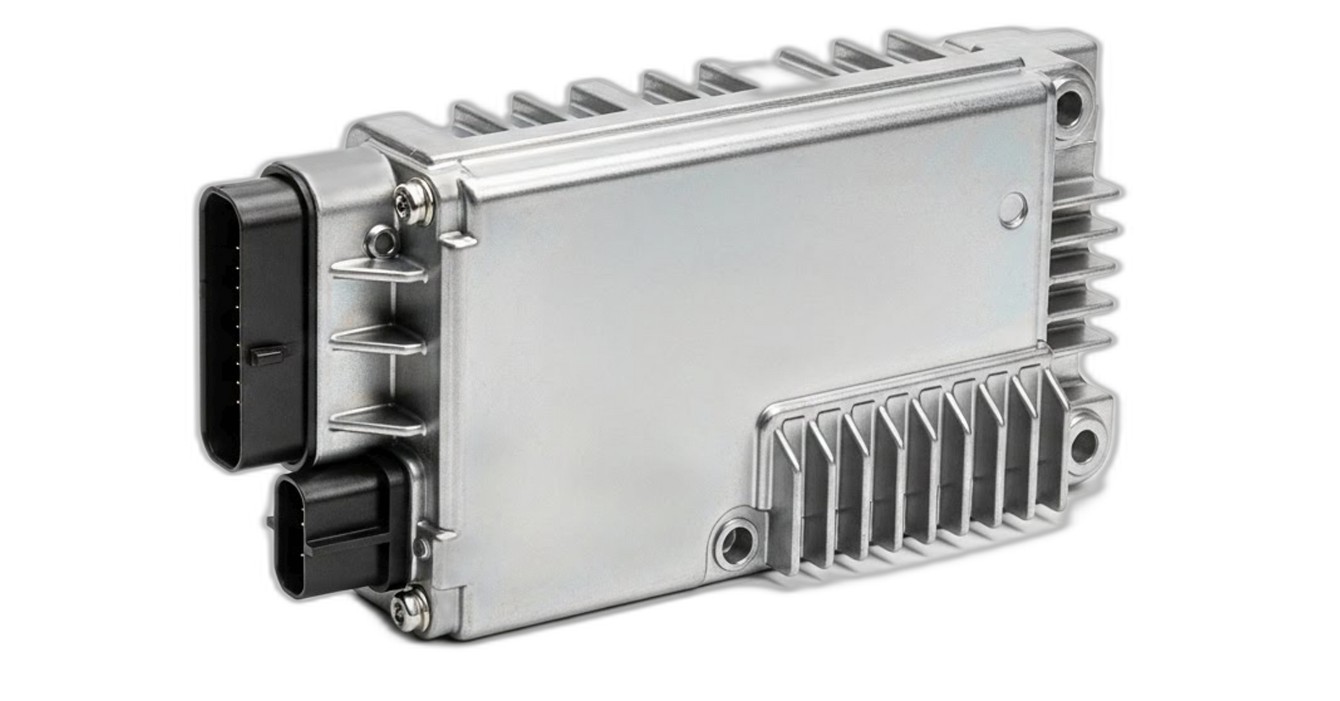

Designing Sealing Strategies for Next-Generation Control Units

As electronics become more central to vehicles, industrial machines, and connected devices, the demands placed on control units are intensifying…

Leak Testing for Heat, Vibration, and Outdoor Exposure

Electronics used in automotive, telecom, and industrial environments must survive far more than basic IP rating tests…

A Practical Roadmap for Fast, Stress-Free CCI Qualification

Container closure integrity (CCI) expectations have shifted dramatically in recent years…

How Leak Test Data Helps Predict Packaging Failures Before They Happen

Most packaging failures do not appear suddenly. They develop slowly, often hidden within small variations in sealing, drift in test equipment, or subtle shifts in packaging materials…

Season’s Greetings from Nolek

As the year comes to a close, we’d like to take a moment to say a sincere thank you to all of our customers and partners…