As electronics manufacturing expands across continents, consistency becomes a competitive advantage. For global OEMs producing control boxes, sensor housings, or communication modules…

Designing for First-Pass Yield: Leak Testing Strategies That Scale

In fast-moving manufacturing environments, getting it right the first time is critical, which is where First-pass yield (FPY) comes into play. It tells you how well your process is running…

How to Design a Flexible Leak Testing Process for Rapid Device Innovation

Innovation in medical device development is moving faster than ever. As timelines shorten and product iterations accelerate, quality processes must keep pace, especially when it comes to leak testing. Whether you’re launching a next-gen drug package or refining an existing assembly,…

Non-Destructive Leak Testing for Medical Devices: Myths, Methods, and Must-Haves

For manufacturers of sterile medical devices, leak testing plays a critical role in maintaining patient safety, meeting regulatory requirements, and delivering consistent product quality. But despite its importance, leak testing is often misunderstood, misapplied, or underestimated, especially when it comes to…

Vacuum Decay vs. Helium Leak Testing: Which Is Best for Your Pharma Packaging?

When it comes to packaging for pharmaceuticals and sterile injectables, leak testing is not optional. Whether you are producing parenteral vials, syringes, plasma bags or blister packs, a compromised seal can put patients at risk and result in product recalls, failed…

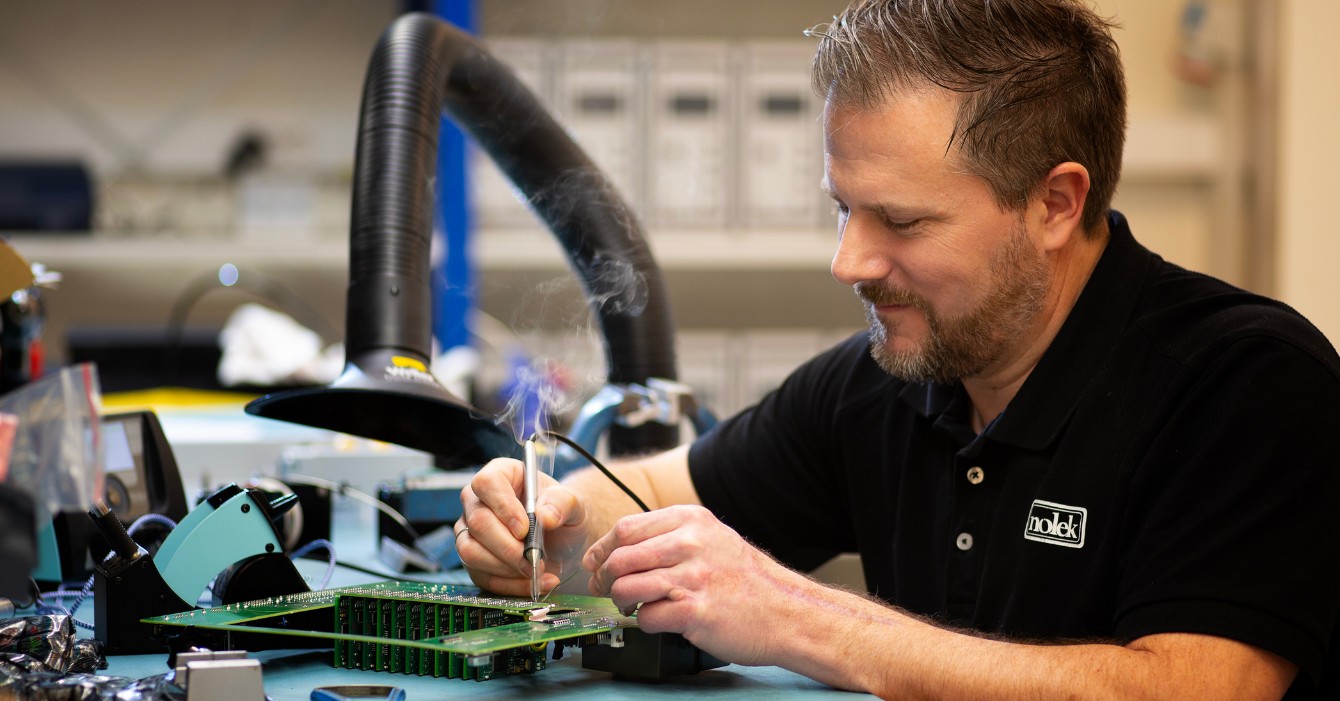

Our own leak detection tool is almost complete

We have been working very hard over the past year in distilling our years of experience in the leak detection and testing industry into our own tool for leak detection. Now we’re happy to say that we are almost at the…