Helium leak testing is one of the most accurate and sensitive methods for detecting micro-leaks in sealed components. But for many manufacturers, it comes with a frustrating problem: false positives.

You run the test. The system flags a leak. You retest the same part, and it passes. What’s going on?

The culprit is often residual helium gas lingering in your test chamber or fixtures, especially in setups where chambers are shared across different products or shifts. If you’ve been chasing phantom leaks, it’s time to look beyond the part and start thinking about your test environment.

Why False Positives Happen in Helium Leak Testing

Helium is lightweight, inert, and tiny, ideal for leak detection, but difficult to manage if it’s not fully purged from your test system. Here’s where it typically causes problems:

1. Residual Helium in the Test Chamber

If helium from a previous test isn’t fully vented, it can skew baseline readings. This is particularly common in vacuum test chambers with complex geometries or insufficient purge cycles.

2. Tooling and Fixture Retention

Helium can become trapped in porous materials, long hoses, seals, or adapters. Over time, it off-gasses slowly, contaminating subsequent tests.

3. Inadequate Ventilation Between Tests

Without proper timing or flow controls, even a slight delay in chamber ventilation can lead to helium accumulation, especially in high-throughput production environments.

4. Environmental Cross-Contamination

In facilities using helium in other processes, such as calibration labs, R&D, or welding bays, it can linger in ambient air and drift into sensitive testing areas.

How to Prevent False Positives and Trust Your Results

Reducing false positives in helium testing is less about the part and more about system control. Here’s how Nolek helps customers solve it:

Optimise Chamber Design

Our engineers evaluate chamber shape, volume, and fixture materials to reduce dead zones where helium can collect. Strategic baffling and internal flow guides improve venting performance.

Calibrate Venting and Dwell Cycles

Custom purge timing and dwell periods ensure all helium is evacuated before the next test. Nolek systems can be programmed with adaptive cycles that respond to environmental changes.

Select Low-Absorption Materials

We recommend non-porous materials for fixtures and gaskets, and can help retrofit existing tooling to reduce helium absorption and off-gassing.

Isolate Testing Zones

For customers operating in helium-heavy environments, we advise physical separation, positive-pressure enclosures, or filtered airflows to protect test integrity.

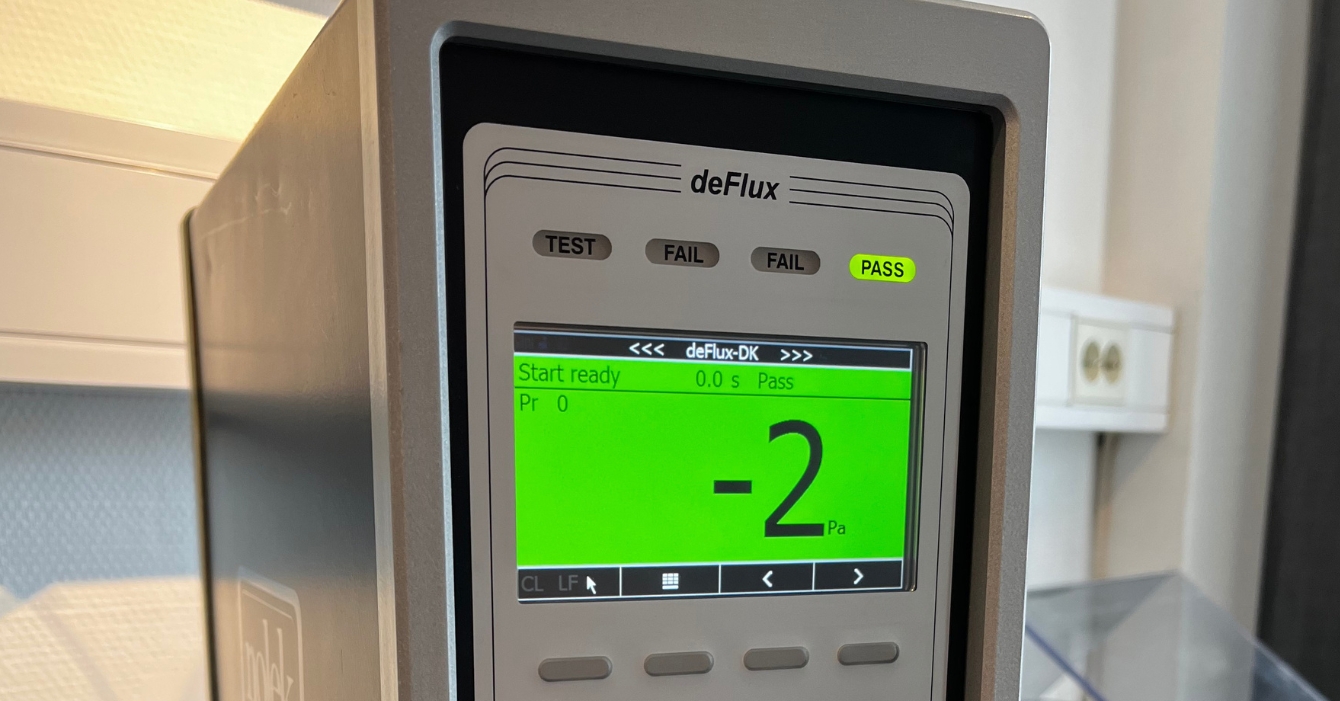

Integrate Real-Time Monitoring

Our systems can be configured to monitor baseline helium levels and flag drift over time. This helps teams correct small deviations before they lead to false results.

The Bigger Picture: Accuracy That Builds Confidence

Every false positive adds cost, wasted time, re-inspection, or even unnecessary rejection of good parts. Worse, it undermines confidence in your test system.

By addressing helium contamination at the system level, you can restore trust in your results and maintain the high sensitivity that helium testing is known for.

At Nolek, we don’t just sell leak testers, we help you configure, fine-tune, and maintain a leak testing process you can rely on, every time.

What’s Next?

If you’re dealing with inconsistent test results or unexplained leak flags, let’s take a closer look together.