Electronics used in automotive, telecom, and industrial environments must survive far more than basic IP rating tests…

A Practical Roadmap for Fast, Stress-Free CCI Qualification

Container closure integrity (CCI) expectations have shifted dramatically in recent years…

How Leak Test Data Helps Predict Packaging Failures Before They Happen

Most packaging failures do not appear suddenly. They develop slowly, often hidden within small variations in sealing, drift in test equipment, or subtle shifts in packaging materials…

Season’s Greetings from Nolek

As the year comes to a close, we’d like to take a moment to say a sincere thank you to all of our customers and partners…

How Drift Quietly Damages Quality Systems

Most manufacturers think of calibration as a routine chore, a scheduled task carried out every few months…

Standardizing Leak Testing Across Global Sites

Global manufacturers often struggle to maintain consistent leak testing practices across multiple plants…

How to Avoid Over-Testing and Protect Yield

Modern pharma and MedTech production teams face a familiar tension: regulators expect robust, deterministic leak detection…

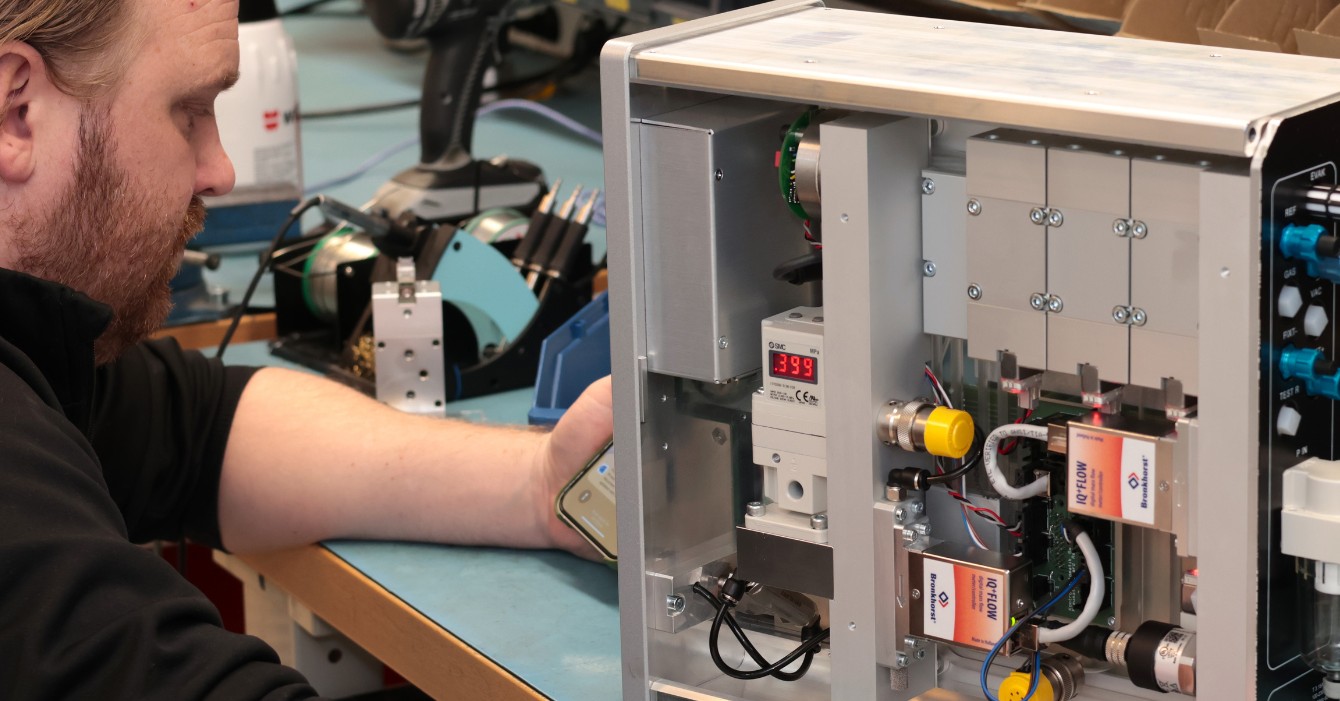

Proving Environmental Protection with Advanced Leak Testing

An IP rating on a product may look impressive, but for electronics manufacturers, a label on paper is only the beginning…

4 Causes of Leak Test Failures

Leak test failures can be frustrating. You’ve got parts to ship, auditors to satisfy, and operators waiting for answers, yet your test results are inconsistent…

Preventive Leak Test Service Contracts That Pay Off

What costs more than a failed leak test? The hours of lost production that follow. In industries where uptime is everything, waiting for your leak tester to break down is like…